- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Alumina (al2o3) Mga Manufacturer, Supplier, Factory

- View as

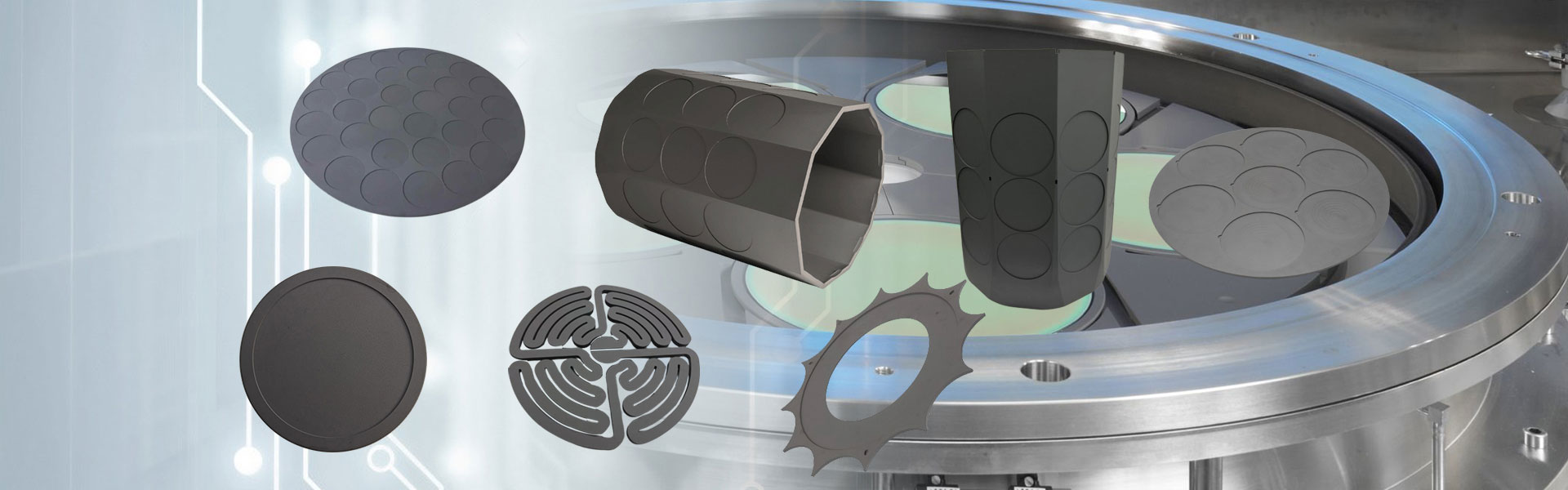

Al2O3 Vacuum Chuck

Ang Semicorex Al2O3 Vacuum Chuck ay idinisenyo upang matugunan ang mahigpit na pangangailangan ng iba't ibang proseso ng produksyon ng semiconductor, kabilang ang pagnipis, pag-dicing, paglilinis, at pagdadala ng mga wafer. **

Magbasa paMagpadala ng InquiryAlumina Ceramic Vacuum Chuck

Inilapat ang Semicorex Alumina Ceramic Vacuum Chuck sa mga proseso ng pagnipis at paggiling ng wafer ng paggawa ng semiconductor, na nagsisilbing isang kailangang-kailangan na tool para makamit ang mataas na katumpakan at maaasahang produksyon ng semiconductor.**

Magbasa paMagpadala ng InquiryESC Chuck

Ang Semicorex ESC Chuck ay isang kritikal na bahagi sa industriya ng semiconductor, partikular na idinisenyo upang ligtas na humawak ng mga wafer sa panahon ng iba't ibang proseso ng paggawa. Nagbibigay ang Semicorex ng mga de-kalidad na produkto sa mapagkumpitensyang presyo, handa kaming maging iyong pangmatagalang kasosyo sa China.*

Magbasa paMagpadala ng InquiryE-Chuck

Ang Semicorex E-Chuck ay isang advanced electrostatic chuck (ESC) na partikular na idinisenyo para sa mga application na may mataas na pagganap sa industriya ng semiconductor. Ang Semicorex ay isang nangungunang tagagawa para sa semiconductor sa China.*

Magbasa paMagpadala ng InquiryBraso ng Wafer Loader

Ang kakayahan ng Semicorex Wafer Loader Arm na makatiis sa matinding kundisyon habang pinapanatili ang pambihirang performance ay binibigyang-diin ang halaga nito sa pag-optimize ng mga proseso ng pagmamanupaktura at pagkamit ng mas mataas na antas ng produktibidad at kalidad.

Magbasa paMagpadala ng InquiryCeramic Electrostatic Chuck

Ang Semicorex Ceramic Electrostatic Chuck (ESC) ay isang espesyal na tool na meticulously ginawa upang matugunan ang mahigpit na pangangailangan ng semiconductor manufacturing. Sa aming matatag na pangako sa pagbibigay ng mga de-kalidad na produkto sa mapagkumpitensyang presyo, handa kaming maging iyong pangmatagalang kasosyo sa China.*

Magbasa paMagpadala ng Inquiry