- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Alumina (al2o3) Mga Manufacturer, Supplier, Factory

- View as

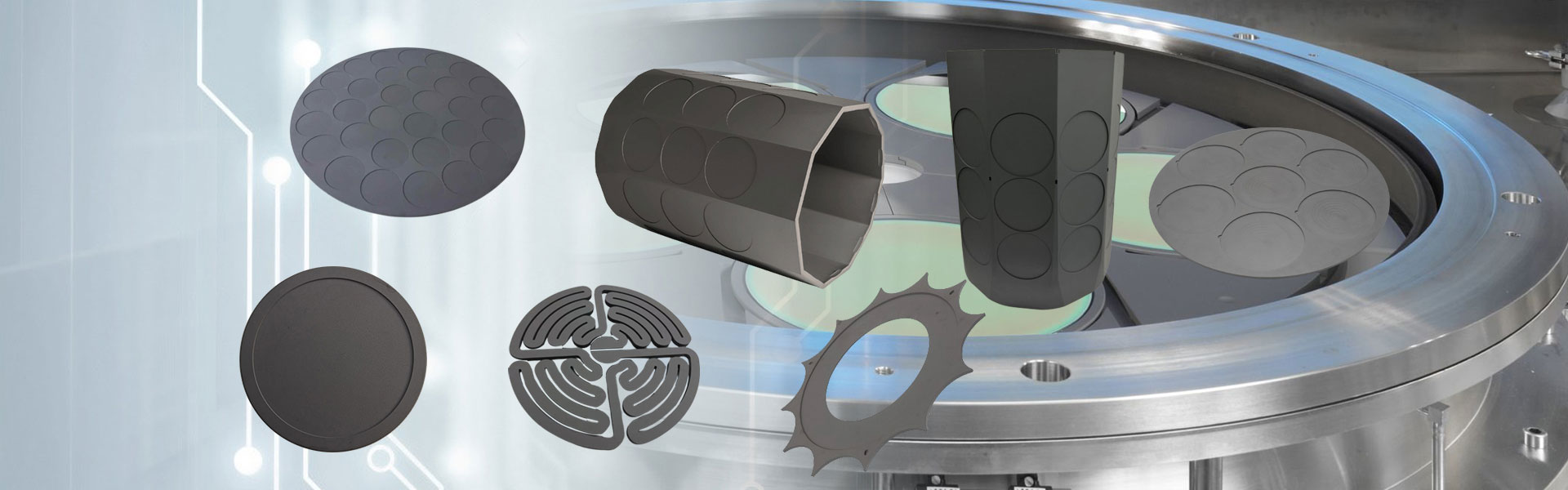

Alumina ceramic end effector

Ang Semicorex alumina ceramic end effector ay isang sangkap na may precision-engineered na partikular na idinisenyo para sa maaasahan at kontaminasyon-free wafer na paghawak sa semiconductor manufacturing at mga kaugnay na aplikasyon.*

Magbasa paMagpadala ng InquiryBuhaghag na Ceramic Chuck

Ang Semicorex Porous Ceramic Chuck (Vacuum Chuck) ay isang high-precision na tool na idinisenyo upang secure na humawak ng mga wafer sa panahon ng mga proseso ng pagmamanupaktura ng semiconductor. Sa pamamagitan ng pagpili sa Semicorex, nakikinabang ka mula sa isang solusyon na nag-aalok ng pambihirang pagganap, tibay, at mga pagpipilian sa pag-customize, na tinitiyak ang pinahusay na kahusayan sa produksyon at pare-pareho ang mga pamantayan ng kalidad.*

Magbasa paMagpadala ng InquiryAlumina Vacuum Chucks

Ang Semicorex Alumina Vacuum Chucks ay precision-engineered na mga bahagi na idinisenyo upang secure na humawak ng mga wafer o substrate sa panahon ng kritikal na semiconductor at precision na proseso ng pagmamanupaktura. Sa pangako ng Semicorex sa mga de-kalidad na materyales at makabagong mga diskarte sa pagmamanupaktura, ang aming Alumina Vacuum Chucks ay nagbibigay ng walang kaparis na pagiging maaasahan, katumpakan, at pagganap para sa iyong pinaka-hinihingi na mga aplikasyon.*

Magbasa paMagpadala ng InquiryVacuum Chuck

Ang Semicorex Vacuum Chuck ay isang high-performance na component na idinisenyo para sa secure at tumpak na paghawak ng wafer sa paggawa ng semiconductor. Piliin ang Semicorex para sa aming mga advanced, matibay, at contamination-resistant na mga solusyon na nagsisiguro ng pinakamainam na performance sa kahit na ang pinakamahirap na proseso.*

Magbasa paMagpadala ng InquiryAlumina Insulation Ring

Ang Semicorex Alumina Insulation Ring ay ginagamit bilang isang insulator sa iba't ibang mga de-koryenteng bahagi, ang mahusay na mga katangian ng pagkakabukod ng kuryente ay nagsisiguro ng maaasahang pagganap sa mga aplikasyon kung saan ang pagpigil sa pagpapadaloy ng kuryente ay mahalaga.

Magbasa paMagpadala ng InquiryAlumina Wafer Polishing Carrier

Ang aplikasyon ng Semicorex Alumina Wafer Polishing Carrier sa iba't ibang industriya, mula sa semiconductors hanggang sa photovoltaics, na gumaganap ng isang mahalagang papel sa mga proseso ng paggiling at kemikal na mechanical polishing (CMP) ng mga wafer.

Magbasa paMagpadala ng Inquiry