- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Alumina (al2o3) Mga Manufacturer, Supplier, Factory

Alumina ceramics are a type of advanced ceramic material that is primarily made of aluminum oxide and the general purpose of ceramists. They are in great demand because of their remarkable comprehensive properties, some of which include high hardness, high wear resistance, and high temperature resistance. These will maintain their structure at very high temperatures. Additionally, alumina ceramics have high electrical insulation and chemical resistance, and very high mechanical strength. While brittleness will limit them. They possess all those properties which has resulted in alumina ceramics playing a central role in the semiconductor industry.

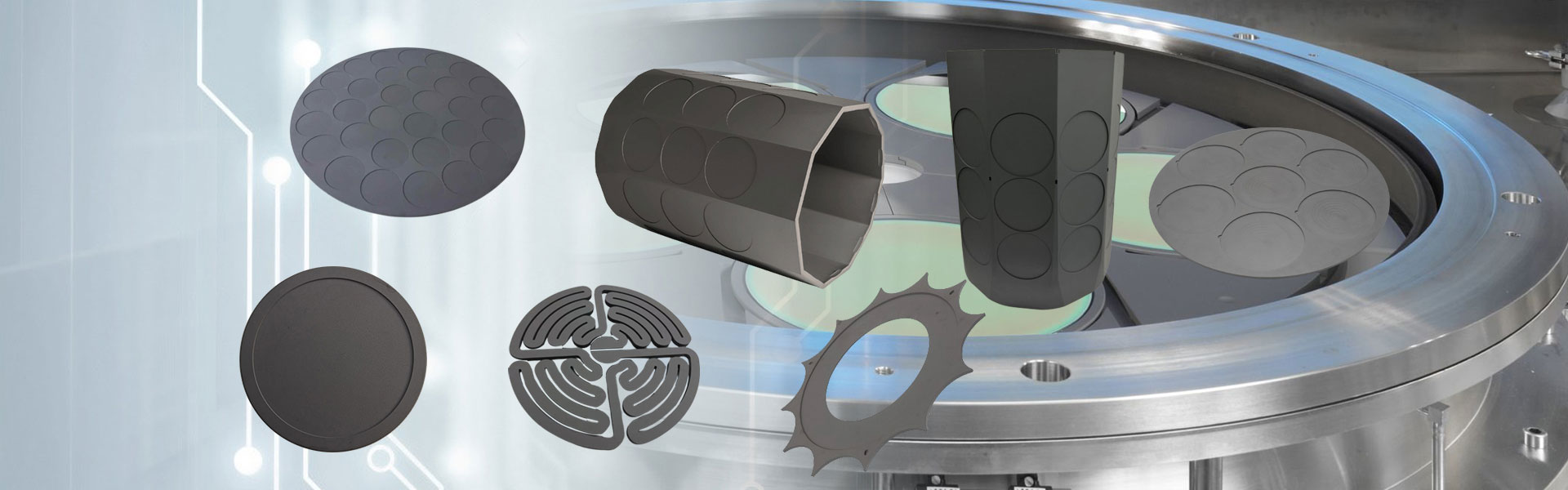

The vacuum chuck will be attached to the vacuum equipment via a connecting pipe. When the chuck comes in contact with the workpiece, i.e., a sheet or film, the vacuum equipment will activate and draw negative pressure in the chuck. The workpiece is carried by atmospheric pressure thus it will cling firmly to the chuck allowing the processing to go on without issue. When the workpiece is done being processed the vacuum machine will stop and the chuck will gradually fill with air. The workpiece will separate of its own accord thus finishing the clamping, processing and handling processes.

Black Alumina ceramic is one of the primary materials used in vacuum chucks. It is primarily composed of Al2O3, with transition metal oxides as colorants and sintering aids added. The process is then sintered at a specific temperature. Vacuum chucks made from porous ceramic feature ultra-fine micrometer-level pores and spacing, enabling reliable handling of thinner and more delicate workpieces. Furthermore, these chucks can accommodate workpieces of varying sizes, eliminating the need to maintain a fixed set of shapes and sizes for each workpiece, thus saving costs and improving efficiency.

Alumina ceramics have a high elastic modulus and specific stiffness, are resistant to deformation, and have a low coefficient of thermal expansion and high thermal stability. They are an excellent structural material and are currently widely used in aviation, aerospace, petrochemicals, machinery manufacturing, the nuclear industry, and microelectronics.

Alumina ceramic components offer excellent properties such as high hardness, high mechanical strength, exceptional wear resistance, high temperature resistance, high resistivity, and excellent electrical insulation. They can meet the complex performance requirements of semiconductor manufacturing in special environments such as vacuum and high temperature. They play an irreplaceable and important role in semiconductor manufacturing production lines, covering nearly all semiconductor manufacturing equipment and serving as key components. Alumina ceramic components are primarily categorized by application, including annular and cylindrical types, airflow guides, load-bearing and fixed types, hand-grip gaskets, and modules.

- View as

Polycrystalline alumina fiberboard

Ang polycrystalline alumina fiberboard ay isang mataas na pagganap na refractory plate na materyal na may mahusay na thermal shock resistance, malakas na paglaban ng kaagnasan at mahusay na paglaban sa oksihenasyon. Ang pagganap ng refractory na ito ay ginagawang malawak na ginagamit sa mapaghamong mga kapaligiran na may mataas na temperatura, kabilang ang mga hurno ng mataas na temperatura, mga mataas na temperatura, mga high-temperatura na reaktor, mga high-temperatura na pipelines, mga pader na may mataas na temperatura, mga pader na may mataas na temperatura. Ang pagpili ng Semicorex, makikinabang ka mula sa lubos na mga presyo na magastos, isinapersonal na one-on-one na serbisyo sa pagpapasadya, at pambihirang kalidad ng produkto.

Magbasa paMagpadala ng InquiryNapapasadyang mga ceramic nozzle

Ang panindang may masidhing pansin sa detalye, napapasadyang mga ceramic nozzle mula sa semicorex ay ang solusyon sa henyo para sa pagkontrol sa daloy ng rate ng parehong mga gas at likido na may walang kaparis na pagkakapareho at katumpakan. Inaasahan ng Semicorex ang iyong karagdagang konsultasyon.

Magbasa paMagpadala ng InquiryCeramic electrostatic chucks

Ang Semicorex ceramic electrostatic chuck ay katumpakan ng mga sangkap na electrostatic adsorption na gawa sa mataas na pagganap na alumina at aluminyo nitride ceramics, na gumagamit ng prinsipyo ng electrostatic adsorption sa clamp at ayusin ang mga wafer. Malawakang ginagamit ito sa mga patlang ng pagmamanupaktura ng semiconductor. Ang Semicorex ay may advanced na teknolohiya, de-kalidad na mga materyales, at mga produktong epektibo sa gastos. Inaasahan namin ang pagiging iyong maaasahang kasosyo sa supply sa China.

Magbasa paMagpadala ng InquiryAlumina ceramic manipulator

Ang Semicorex alumina ceramic manipulator ay isang mataas na pagganap na sangkap na kagamitan sa semiconductor na gawa sa high-purity alumina, na ininhinyero para sa tumpak na paghawak ng mga wafer na walang kontaminasyon. Ang manipulator na ito ay may mga katangian ng pambihirang kalinisan, higit na katatagan, mataas na katumpakan, pinahusay na kahusayan at maaasahang pagganap, ginagawa itong iyong mainam na pagpipilian.

Magbasa paMagpadala ng InquiryAlumina mounting base plate

Ang Semicorex alumina mounting base plate ay mataas na pagganap na ceramic na sangkap na idinisenyo para sa tumpak na paghawak ng wafer sa paggawa ng semiconductor. Ang higit na mahusay na lakas, pagkakabukod, at katatagan ng thermal ay ginagawang perpekto para sa paghingi ng mga kapaligiran sa automation ng cleanroom.*

Magbasa paMagpadala ng InquiryARMINA ROBOT ARM

Ang Semicorex alumina robot braso ay isang mataas na pagganap na ceramic na sangkap na idinisenyo para sa tumpak na paghawak ng wafer sa paggawa ng semiconductor. Ang higit na mahusay na lakas, pagkakabukod, at katatagan ng thermal ay ginagawang perpekto para sa paghingi ng mga kapaligiran sa automation ng cleanroom.*

Magbasa paMagpadala ng Inquiry