- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

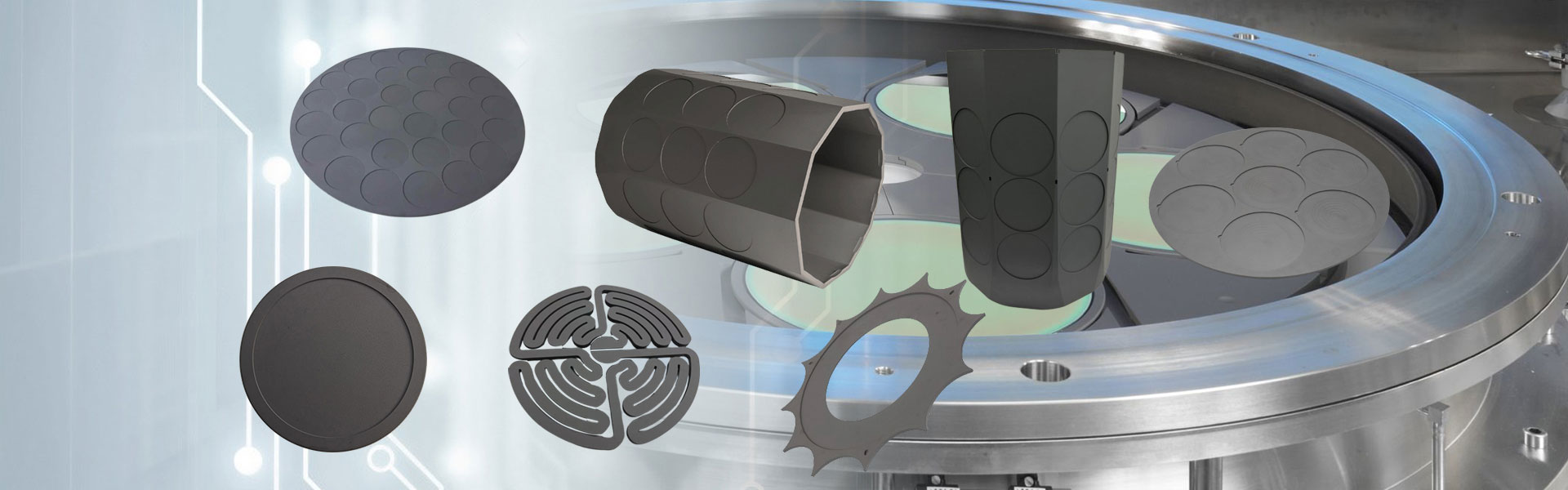

China Isostatic grapayt Mga Manufacturer, Supplier, Factory

- View as

Bronze grapayt bushing

Ang Semicorex tanso na grapayt na bushing ay may mga katangian ng kapasidad na may mataas na pag-load, paglaban sa epekto, paglaban sa mataas na temperatura, malakas na kakayahan sa self-pagpapadulas, at maaari ring makatiis sa pagguho at pag-aaklas ng mga kinakaingal na likido. Ang tanso na graphite bushing na ito ay partikular na angkop para sa mga kagamitan na nagpapatakbo sa ilalim ng mga kumplikadong kondisyon sa pagtatrabaho kung saan ang walang langis, mataas na temperatura, high-load, low-speed, anti-fouling, anti-corrosion, at anti-radiation environment.

Magbasa paMagpadala ng InquirySelf-lubricating bearings

Ang Semicorex self-lubricating bearings ay isang uri ng tindig na pinagsasama ang mga self-lubricating na katangian ng mga graphic na materyales. Malawakang ginagamit ang mga ito sa mga larangan ng pang -industriya na may mataas na mga kinakailangan sa pagpapadulas at kumplikadong mga kondisyon sa kapaligiran.

Magbasa paMagpadala ng InquiryGraphite Rod Heater

Ang Semicorex Graphite Rod Heater ay isang elemento ng pag-init ng mataas na pagganap na idinisenyo para sa pantay na henerasyon ng mataas na temperatura sa loob ng mga hurno ng vacuum. Piliin ang Semicorex para sa kadalubhasaan nito sa mga solusyon sa graphite na may katumpakan, na naghahatid ng higit na mataas na katatagan ng thermal at pangmatagalang pagganap na naaayon sa iyong pang-industriya na pangangailangan.*

Magbasa paMagpadala ng InquiryGraphite electrode rod

Ang Semicorex Graphite Electrode Rods ay mga sangkap na may mataas na kadalisayan na ginagamit bilang mga elemento ng pag-init ng core sa mga hurno ng vacuum. Piliin ang Semicorex para sa hindi magkatugma na kalidad ng materyal, machining ng katumpakan, at maaasahang pagganap sa mga kapaligiran na may mataas na temperatura.*

Magbasa paMagpadala ng InquiryGraphite top plate

Ang Semicorex Graphite Top Plates ay mga fixtures na inhinyero na dinisenyo para sa ligtas at maaasahang paghawak ng mga mainit na bote ng baso sa mga kapaligiran sa pagmamanupaktura ng mataas na temperatura. Piliin ang Semicorex para sa hindi magkatugma na kalidad ng materyal, pasadyang mga kakayahan sa machining, at pare -pareho ang pagganap na pinagkakatiwalaan ng mga nangungunang mga tagagawa ng salamin sa buong mundo.*

Magbasa paMagpadala ng InquiryGraphite crucibles

Ang Semicorex Graphite Crucibles na ininhinyero para sa pambihirang thermal stabil at control control sa mga proseso ng paglago ng kristal ng semiconductor. Piliin ang aming mga grapayt na crucibles para sa hindi katumbas na kadalisayan, pagganap, at pagiging maaasahan sa paglaki ng kristal ng semiconductor. *

Magbasa paMagpadala ng Inquiry