- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

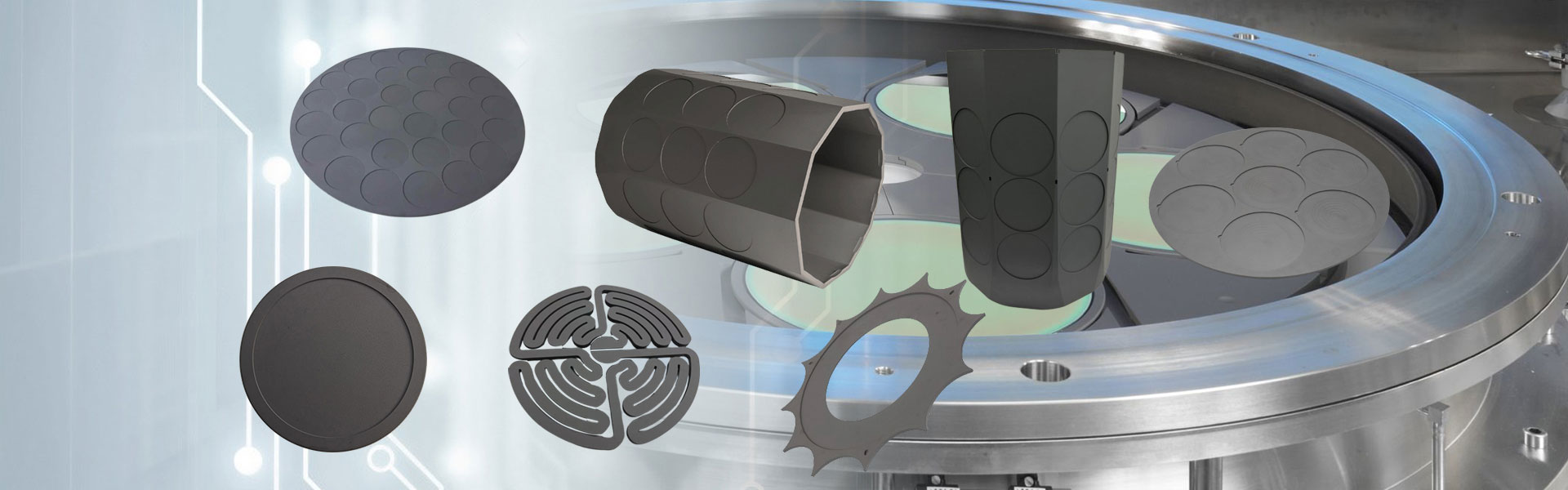

China Isostatic grapayt Mga Manufacturer, Supplier, Factory

- View as

Graphite Chuck

Ang Semicorex Graphite Chuck ay isang mahalagang sangkap sa paggawa ng polysilicon, na malawakang ginagamit sa industriya ng solar. Habang tumataas ang demand para sa mga high-kadalisayan na mga wafer ng silikon, ang pangangailangan para sa mga tool sa pagproseso ng mataas na pagganap tulad ng mga grapayt na chuck ay naging mahalaga. Ang panindang mula sa mataas na kadalisayan ng specialty grapayt, ang aming mga grapiko na chuck ay idinisenyo upang mapaglabanan ang matinding temperatura, pagkakalantad ng kemikal, at mga mekanikal na stress habang pinapanatili ang dimensional na katatagan.*

Magbasa paMagpadala ng InquiryGraphite Rotor at Shaft

Ang mga semicorex graphite rotor at shaft assemblies ay mga mahahalagang bahagi na kadalasang ginagamit para sa degassing sa pagtunaw ng mga aluminyo at aluminyo na haluang metal.

Magbasa paMagpadala ng InquiryGraphite Heat Shield

Upang matiyak ang pagiging epektibo ng pagproseso sa malupit na kapaligiran, ang Semicorex Graphite Heat Shields ay ginawa gamit ang mga premium na graphite na materyales at cutting-edge na teknolohiya sa pagmamanupaktura.

Magbasa paMagpadala ng InquiryGraphite Heating Industrial Element

Ang Semicorex graphite heating industrial element ay isa sa pinakamahalagang bahagi ng high-temperature vacuum sintering furnaces. Ito ay mahalaga para sa iba't ibang mga thermal na proseso dahil sa kanilang mga sopistikadong materyal na katangian.

Magbasa paMagpadala ng InquiryGraphite Bushing

Ang Semicorex Graphite Bushing, na may mga natatanging katangian ng materyal at kakayahang umangkop, ay gumaganap ng isang kritikal na papel sa pagpapahusay ng pagganap at mahabang buhay ng mga mekanikal na sistema, na binibigyang-diin ang kahalagahan nito sa mga modernong proseso ng engineering at pagmamanupaktura.

Magbasa paMagpadala ng InquiryGraphite Ring

Ang kakayahan ng Semicorex Graphite Ring na makatiis sa matinding kundisyon at kadalian ng pag-install ay ginagawa silang isang kailangang-kailangan na bahagi sa mga industriya tulad ng hydraulics, pneumatics, at heat exchangers.

Magbasa paMagpadala ng Inquiry