- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China SI epitaxy Mga Manufacturer, Supplier, Factory

- View as

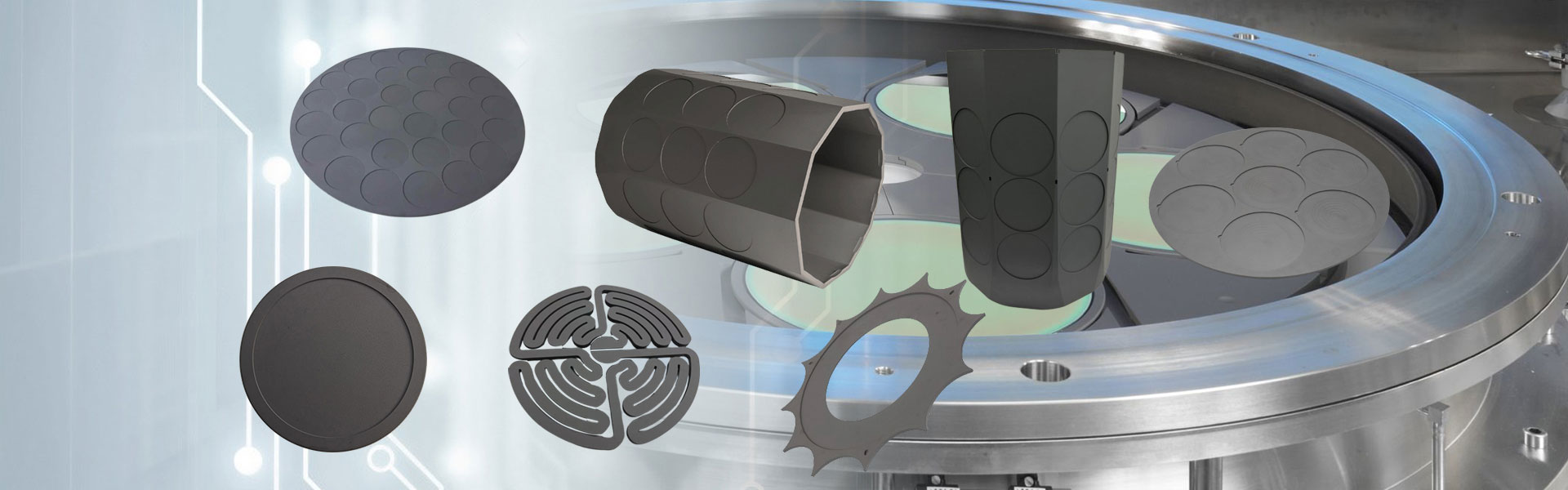

Barrel Susceptor na may SiC Coating

Ang Semicorex Barrel Susceptor na may SiC Coating ay isang cutting-edge na solusyon na idinisenyo upang pataasin ang kahusayan at katumpakan ng mga proseso ng silicon epitaxial. Ginawa nang may masusing atensyon sa detalye, ang Barrel Susceptor na ito na may SiC Coating ay iniakma upang matugunan ang mga hinihinging pangangailangan ng paggawa ng semiconductor, na nagsisilbing pinakamainam na may hawak ng wafer at pinapadali ang tuluy-tuloy na paglipat ng init sa mga wafer. Ang Semicorex ay nakatuon sa pagbibigay ng mga de-kalidad na produkto sa mapagkumpitensyang presyo, inaasahan naming maging iyong pangmatagalang kasosyo sa China.

Magbasa paMagpadala ng InquirySiC Barrel para sa Silicon Epitaxy

Ang Semicorex SiC Barrel Para sa Silicon Epitaxy ay isang engineered upang matugunan ang hinihingi na mga kinakailangan ng Applied Materials at LPE units. Ginawa nang may katumpakan at pagbabago, ang hugis-barrel na susceptor na ito ay ginawa mula sa mataas na kalidad na SiC-coated graphite, na tinitiyak ang pambihirang pagganap at tibay sa mga aplikasyon ng silicon na epitaxy. Ang Semicorex ay nakatuon sa pagbibigay ng mga de-kalidad na produkto sa mapagkumpitensyang presyo, inaasahan naming maging iyong pangmatagalang kasosyo sa China.

Magbasa paMagpadala ng InquiryGraphite Susceptor na may SiC Coating

Ang Semicorex Graphite Susceptor na may SiC Coating ay isang mahalagang bahagi na idinisenyo para sa mga proseso ng silicon epitaxy sa Applied Materials at LPE (Liquid Phase Epitaxy) unit. Ginawa mula sa de-kalidad na materyal na grapayt na pinahiran ng Silicon Carbide (SiC), tinitiyak ng susceptor na ito ang mahusay na pagganap at mahabang buhay sa mga kapaligiran sa pagmamanupaktura ng semiconductor. Ang Semicorex ay nakatuon sa pagbibigay ng mga de-kalidad na produkto sa mapagkumpitensyang presyo, inaasahan naming maging iyong pangmatagalang kasosyo sa China.

Magbasa paMagpadala ng Inquiry